-

PX 07 primer filler:

PX 07 primer filler:surface darkening prevention.

-

PX 07 primer filler:

PX 07 primer filler:enhances surface coating application rate.

-

PX 07 primer filler:

PX 07 primer filler:increases paint adhesiveness and coating durability.

-

PX 07 primer filler:

PX 07 primer filler:surface darkening prevention.

Primer filler PX 07 – surface darkening prevention

Primer filler for antigraffiti coatings

PX 07 is a single-component, colourlessly drying dispersion of styrene-acrylic copolymer. It is used for priming absorptive, mineral substrates before application of anti-graffiti coating, which minimises or prevents the covered surface form darkening. It also enhances and evens out its absorptiveness. The product perfectly penetrates into the surface while improving its adhesive properties thanks to small size dispersion particles. PX 07 allows diffusion, has hydrophobic properties, protects the surface from penetration by hazardous substances and is UV and erosion resistant.

Product key qualities:

The PX 07 primer we offer our customers is a unique product. Below you will find the most important advantages of this unique product:

- prevents colour deepening or colour changes,

- single-component preparation- easy application,

- vapour-permeable,

- strengthens substrates, paint layers, delicate natural stones,

- equalises and stabilises absorption on all absorbent substrates,

- increases the adhesion of paints to the substrate and the durability of the coating,

- improves the performance of topcoats,

- Provides excellent adhesion to a different mineral substrates,

- improves weathering resistance of substrates,

- increases the hydrophobicity of coatings,

- very good penetration,

- highly durable,

- can be used on a variety of absorbent substrates,

- application by roller, brush, air and airless spraying.

How does PX 07 primer work?

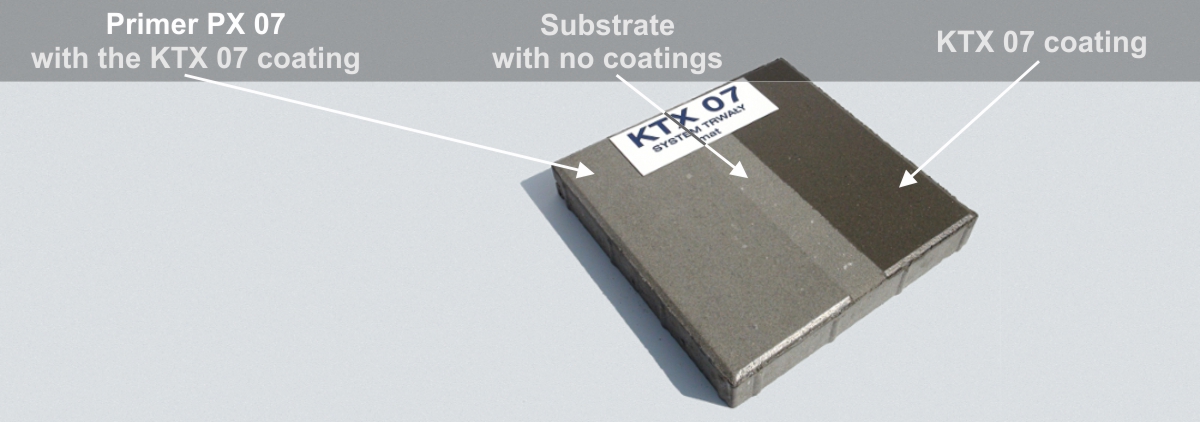

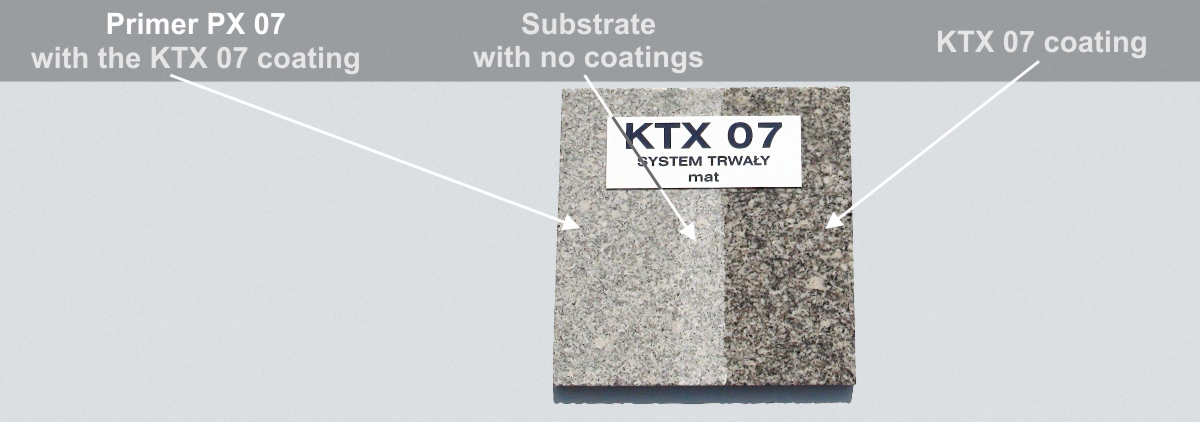

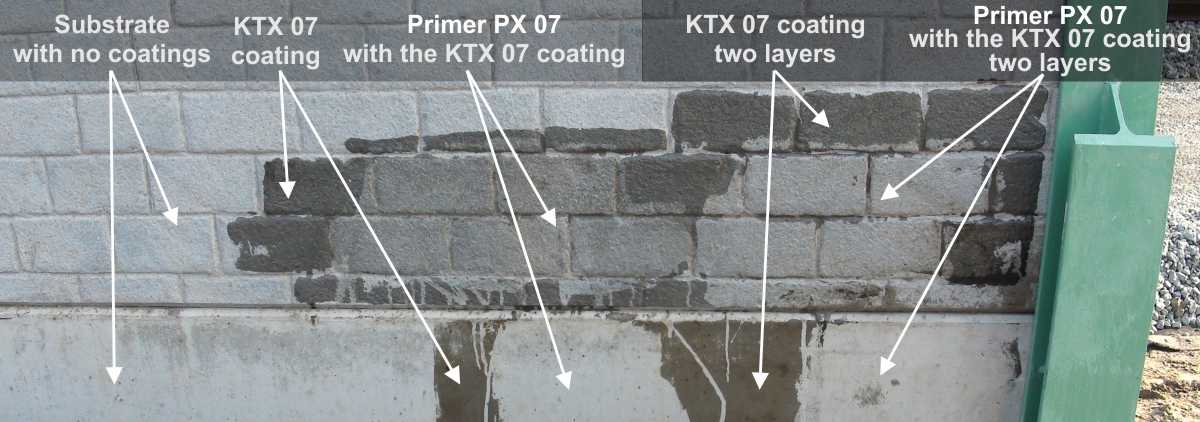

Examples of surfaces with PX 07 on variety of materials

We present an example of how the PX 07 primer works on concrete surface with different levels of absorbency. As the absorbency of the surface increases, the intensity of the darkening of its color increases after applying the anti-graffiti coating. PX 07 significantly reduces this phenomenon.

Substrate with low absorbency:

Substrate with high absorbency:

Technical data on application

On drying, the primer constitutes a transparent film, hardly visible or entirely invisible depending on the surface type, amount of sunlight and incidence angle. The product shows lack of significant reduction in water vapour diffusion, UV resistance, resistance to alkalis, dries without becoming sticky.

Areas for application

PX 07 can be used both on smooth and porous absorptive substrates. Thanks to extremely small particle size it can be recommended for most absorptive mineral substrates such as: concrete, cement, mortar, plaster boards, brick, clinker and natural stone e.g. sandstone, travertine and granite. The product is highly resistant to alkalis so it can be applied on cement or cement-lime mortar. It can also be used prior to application of other paint coats. Due to the variety of covered substrates it is advisable to test the product's reaction with the surface first, before its actual application.

Application method

After opening the container stir all the contents thoroughly. On pouring out a suitable portion, close the lid firmly to prevent water from vaporising and a film from forming on the surface.

PX 07 application:

- surrounding temperature +5°C to +30°C,

- relative air humidity: up to 90%,

- substrate humidity: below 6%.

The temperature must be stable and remain within the appropriate range throughout the drying period. The product must be applied thoroughly filling all cracs and irregularities in the surface. Negligence this may result in the surface darkening, which can be visible after application of the anti-graffiti coating.

The product can be applied in one or two layers, depending on the surface:

- very absorptive substrates e.g. concrete should be painted twice,

- low absorptive substrates e.g. granite should be painted once,

- substrates previously hydrophobicized can be painted once or twice.

Drying time PX07 at 22°C:

- 10 min. dust-dry,

- 20 min. touch-dry, externally cured, no fingerprints left when touched,

- 40 min. cured.

Allow for about 1 hours' break between applying the first and second layers at the temp. of 22°C. All layers should be applied in one working cycle. Protected primed substrate from rain until the coating is applied. Anti-graffiti coating should be applied to the primed substrate after complete evaporation of water or dry the substrate, min.1 hour. If streaks or splatters appear, they should be smoothened with a roller before drying. The preparation can be used in ventilated room.

Application:

- paint rollers, brushes,

- pneumatic/airless spraying method, nozzle 12 to 18,

- exception are hydrophobized surfaces – in this case apply PX07 primer with a roller. Spray application may cause the “beading” effect on the surface.

Wear

On absorptive substrates, two layers is the optimum application.

Theoretical application rate: 8,3 m²/L (120 ml/m²) up to 16,5 m²/L (60 ml/m²)

Theoretical application rate refers to approximate values indicating extreme consumption amounts which differ according to the type of surface the product is applied to.

Absorptive substrates:

8,3 m²/L (120 ml/m²) per two layers, e.g. sandstone, concrete.

Low absorptive substrates:

approx.16,5 m²/L (60 ml/m²) per one layer, e.g. engineering concrete, granite.

Practical application rate: depends on individual applications in particular cases, incl. conditions existing during application, method of application, shape and roughness of protected surface and also base absorptiveness and loss during application.