-

KTX 30 Coating:

KTX 30 Coating:Fully transparent, one layer is sufficient for full protection.

-

KTX 30 Coating:

KTX 30 Coating:Single-component coating, easy to apply.

-

KTX 30 Coating:

KTX 30 Coating:Restores the natural appearance of damaged, fogged or oxidised surfaces.

-

KTX 30 Coating:

KTX 30 Coating:Fogged glass, polycarbonate and plexiglass recover their transparency.

-

KTX 30 Coating:

KTX 30 Coating:Durable protection allowing repetitive removal of graffiti.

-

KTX 30 Coating:

KTX 30 Coating:Multiple protection – durability of 5 years.

-

KTX 30 Coating:

KTX 30 Coating:Suitable for different substrates.

-

KTX 30 Coating:

KTX 30 Coating:For indoor and outdoor application.

KTX 30 Anti-graffiti Coating – a durable system

Unique transparency is the main quality of this anti-graffiti coating.

Principal characteristics and qualities of KTX 30 coating:

- a durable isomorphic system allows repetitive removal of graffiti;

- single-component preparation – does not require component mixing, does not generate losses caused by the curing of coating that was not used in a specific time – easy application;

- creates a thin (approx. 2 - 6 μm), transparent layer of anti-graffiti coating that is easy to wash out;

- 1 coating layer ensures full protection;

- quick drying – the coating becomes dry in 15 minutes;

- exceptionally high efficiency – up to 111 m²/L;

- vapour permeable;

- graffiti removal with chemical removers;

- anti-adhesive, facilitates tape and poster removal;

- UV-resistant, does not turn yellow; minimum 10-year durability;

- chemical resistance;

- anti-static properties;

- finishing variants:

- matt or gloss;

- renews damaged, fogged or oxidised surfaces and restores their natural gloss;

- application using microfibre rollers, microfibre fabrics, high-volume low-pressure (HVLP) spraying;

- may be applied on any non-absorptive substrates, including polished granite;

- does not cause any loss or optical distortion of transparent surfaces, including glass, polycarbonates, etc.;

- National Technical Assessment, No. IBDiM-KOT-2020/0551 Road and Bridge Research Institute;

- certified – construction mark B.

How does KTX 30 refresh damaged or fogged surfaces?

Example of fogged and scratched polycarbonate sound barriers

Example of fogged and scratched polycarbonate sound barriers

Description of the preparation

KTX 30 is an isomorphic, single-component, translucently drying coating, which constitutes permanent protection against graffiti paints with anti-poster effect. The cured film is entirely transparent and it does not distort nor damage the visual effect of coated substrates. The preparation dries fast, and features very good adhesiveness and durability. Treated surfaces are ideally protected against aerosol graffiti paints and most commercially available markers, dirt, acid rain, alkalis, oil. It hinders permanent sticking of posters, stickers, and adhesive tapes. On its application, KTX 30 constitutes a release liner that prevents substrate penetration and its anti-adhesive properties reduces adhesiveness, often spurring the so-called 'beading' effect in liquid substances/pigments. Surfaces protected with KTX 30, owing to its anti-static properties, remain clean for a long time, which positively limits the costs of cleaning and maintenance, and thus extending service intervals for such surfaces. Protected surfaces exposed to atmospheric conditions facilitate rainwater and snow run-off. KTX 30 features preservative properties and UV filters, owing to which it preserves the colour of protected substrates, and in the case of old, damaged, dull and oxidized surfaces the coating restores their natural look. The preparation is available in two variants:

KTX 30, time to make corrections: approx. 5 minutes.

KTX 30 long, time to make corrections: approx. 20 minutes.

Technical Approval:

Road and Bridge Research Institute No. IBDiM-KOT-2020/0551.

Technical data after application

Appearance on surface: transparent coating with gloss. Graffiti removal: 50 cycles. Coating durability: min.10 years. Dry coating thickness: 2 - 6 μm. Full anti-graffiti protection: after 24 hours. Full curing: after 7 days. The preparation also features anti-corrosive, water-repelling, anti-adhesive and anti-poster properties with high durability and resistance to adverse external factors: thermal, biological or chemical, UV radiation, alkali, corrosion, salt and ammonia solutions, and the majority of solvents. KTX 30 is a durable system facilitating multiple removals of graffiti paints, without the need for coating restoration after graffiti removal.

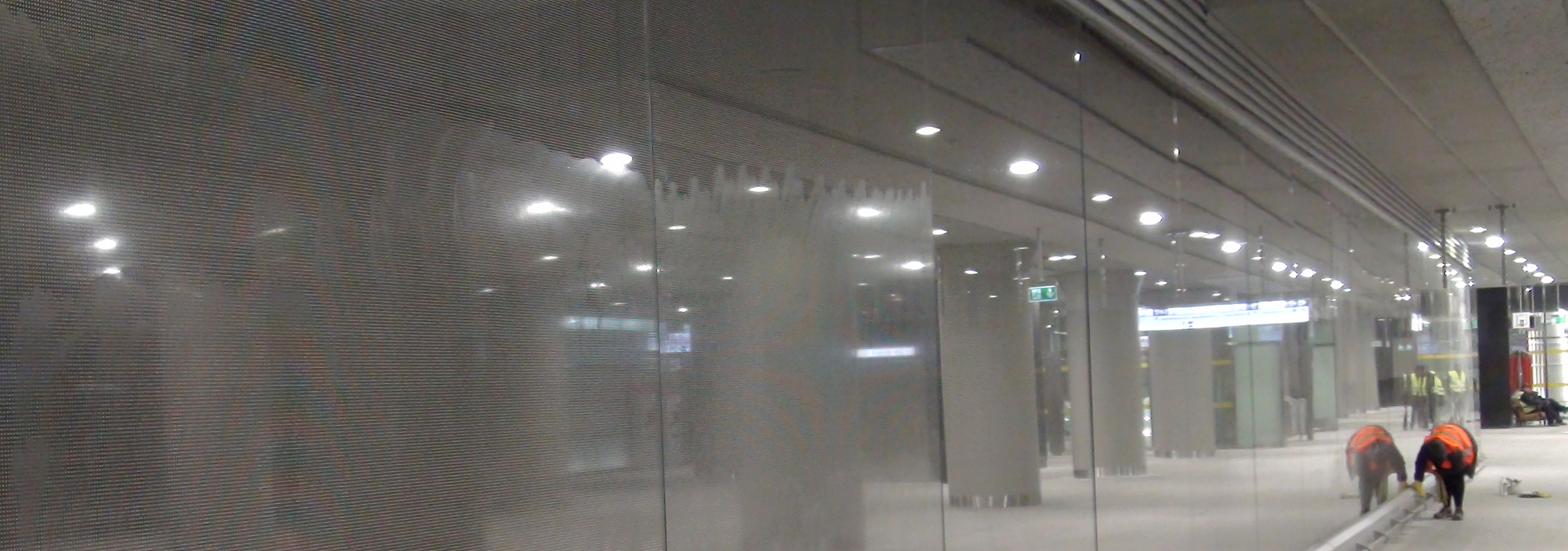

Areas of Application

KTX 30 is suitable for use on hard, non-absorptive surface, e.g.: varnish coatings, powder paint coatings, polyurethane coatings, epoxy coatings, industrial paint coatings; plastics, e.g., polystyrene, ABS, polycarbonates, acrylic glass (plexiglass, polymethyl methacrylate) glass, steel, zinc plated substrates, aluminium, as well as natural stone, such as polished granite. It is applicable on interior and exterior surfaces of trams, buses as well as ticket vending machines, parking meters and lighting poles. Due to its unique translucent properties it is especially recommended for protection acoustic screens made of polycarbonates, acrylic glass and similar materials.

Application method

After opening the container of preparation is ready for use. Before use, do not stir nor shaken the container due to a possibility of and excessive pressure build-up. After pouring the desired amount of the preparation (through a varnish strainer of approx. 125 μm) close the container to prevent impact of humidity and evaporation of the preparation. Apply small portions of the preparation at a time. Do not pour the unused preparation back to the original packaging.

KTX 30 coating application:

- relative air humidity: up to 70%,

- coating application: +5°C to +30°C,

- optimum application temperature: +15°C to +20°C,

- the temperature of the substrate should be at least 3°C above the dew point temperature at that ambient temperature and humidity.

Amount of coating layers:

- the preparation should be applied in one, thin layer.

After curing the coating, it cannot be permanently covered with a second layer. Technological breaks plan on the edges of the wall. If the layer is applied too thick, dried coating is susceptible to cracking.

Drying time KTX 30 at 22°C:

- touch-dry:

- KTX 30: after 15 min.

- KTX 30 long: 40 min. - after 12 hours: cured, resistance to weather conditions,

- after 7 days: complete curing (mechanical and chemical).

Initial anti-graffiti protection properties the coating features after 24 hours. During this period, the coating should not be forcibly wiped/scrubbed.

Mean coating correction time after application on a substrate is at temp. 22°C:

- KTX 30: approx. 5 minutes,

- KTX 30 long: approx. 20 minutes.

Due to the quick drying of the preparation, correction should be done immediately. Anti-adhesive properties of the coating do not allow the application of another layer. During the coating curing time avoid any pollution, including water. The proper temperature range must be maintained throughout the coating curing time; avoid direct sunlight and humidity. Humidity accelerates cross-linking of the coating and affects its quality and tightness. The coating should be applied precisely, so that the treated surface is entirely covered with a film of liquid and a homogeneous layer is created. Failure to do apply the preparation precisely may limit the effectiveness of the anti-graffiti protection. Make sure that no excessive coating should be applied, average consumption is 12ml/m2 and should not be significantly exceeded. If the anti-graffiti coating is applied on newly paint coated substrates, maintain sufficient break time for curing of the paint coating, following Technical Data Sheet of a paint coating system. The coating may be applied outdoors and indoors with proper ventilation. Pay special attention to potential sources of fire. Wind spreads vapours over significant distances.

Application:

Manual: microfibre cloth, window-glass washing pads or lint-free, absorptive fabrics. Another way is to wrap the rubber part of a squeegee or the fabric part of a washing pad with a microfibre cloth. Select suitable application equipment to the size and shape of the treated surface. Apply the coating directly onto a microfibre cloth, not onto the treated substrate. Replace microfibre when it is dirty.

Spraying: the product is applied by means of a pneumatic low pressure (HVLP) spray gun with a 0.7 to 1.3 mm nozzle, under the pressure of 2 to 3 bar.

Use the preparation as a concentrate. Do not mix it with any other liquids.

Wear

The basic principle is to apply 1 layer of full/tight coating. The coating thickness of approx. 2 μm or more provides for sufficient protection. A layer with thickness of 6 μm is applied to matte, absorbent and uneven surfaces. The preparation is very economical in use.

Theoretical spread rate: 66 m²/l (15 ml/m²) up to 111 m²/l (9 ml/m²)

Theoretical spread rate is an approximate value defining the extreme consumption figures, which differ depending on the type of the protected substrate.

Practical spread rate: depends on conditions during application, methods of application and preparation application losses.

Examples of applicators for applying the coating antigraffiti KTX 30

Example applications of KTX 30 anti-graffiti coating:

The Technical Approval required numerous tests of KTX 30, conducted in accordance with the following standards:

- PN-EN 1062-3:2008 Paints and varnishes – Coating materials and coating systems for exterior masonry and concrete – Part 3: Determination of liquid water permeability.

- PN-EN 1542:2000 Products and systems for the protection and repair of concrete structures – Test methods – Measurement of bond strength by pull-off.

- PN-EN 1767:2008 Products and systems for the protection and repair of concrete structures – Test methods – Infrared analysis.

- PN-EN ISO 2811-1:2012 Paints and varnishes – Determination of density – Part 1: Pycnometer method.

- PN-EN ISO 3219:2000 Plastics – Polymers/resins in the liquid state or as emulsions or dispersions – Determination of viscosity using a rotational viscometer with defined shear rate.

- PN-EN ISO 3251:2008 Paints, varnishes and plastics – Determination of non-volatile-matter content.

- PN-EN ISO 7783-2:2001 Paints and varnishes – Coating materials and coating systems for exterior masonry and concrete – Part 2: Determination and classification of water-vapour transmission rate (permeability).

- PN-EN ISO 7783:2012 Paints and varnishes – Determination of water-vapour transmission properties – Cup method.

- PN-EN ISO 9001:2009 Quality management systems – Requirements.

- PN-EN ISO 9001:2009/AC:2009 Quality management systems – Requirements.

- ASTM D6578 Standard Practice for Determination of Graffiti Resistance.

The following test procedure were used in the approval process:

- Test procedure of the Road and Bridge Research Institute: PB/TM-1/13 Assessment of protective coating (or lining) condition after freeze resistance testing.

The following reports of construction product tests were used in the approval procedure:

- Tests by the Road and Bridge Research Institute, Report of the Road and Bridge Research Institute No. TM4/32/2014.